MEET OUR ARTISANS

JHONYS DIAZ

Joined General Cigar in 1998“Tobacco is a living material. As a tobacco person, I'm always trying to find ways to control the tobacco. Yet in the end, the "tobacco always wins". This relationship is very complicated, yet at the same time, it is fun.”

Today, as Senior Vice President, Leaf, Jhonys oversees all tobacco operations, from growing and procurement to processing and manufacturing. Bringing innovation to the premium cigar category, he modestly refers to himself as a “cook”.

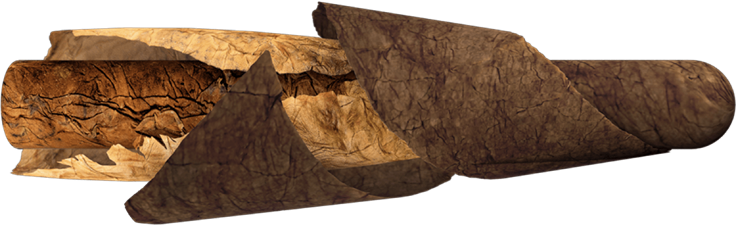

ANATOMY OF CIGARS

- 1

- 2

- 3

Filler

The mixture of leaves constituting the inside of the cigar.

Binder

The cigar leaves wrapped around the filler and keeping it together.

Wrapper

The outer leaf of the cigar which gives the cigar its appearance and colour.

Filler

The mixture of leaves constituting the inside of the cigar. Most often machine-rolled cigars are called short-fillers – i.e. they are made from cut leaves, whereas most often, handmade cigars, so-called long-fillers, are made from whole leaves. Sometimes, tips, filters and flavours are added to machine-rolled cigars, especially in the cigarillo category.

Binder

The cigar leaf wrapped around the filler and keeping it together. The binder can also be HTL (Homogenised Tobacco Leaf). This is typically used on smaller formats.

Wrapper

Some machine-rolled cigars have natural wrappers whereas others have HTL (Homogenised Tobacco Leaf) wrappers.

Handmade cigars take longer to make than machine-rolled cigars and they are more labour-intensive.

Handmade cigars are most often, but not always, made with so-called long-fillers that are tobacco leaves that run the length of the cigar. They can, however, also be made with half tobacco leaves. Handmade cigars are a humidified product.

Machine-rolled cigars are produced in our manufacturing facilities around the world.

While machines mimic the handmade process, they can also produce a more diverse range of products by using smaller pieces of tobacco to deliver good quality cigars at affordable prices for our consumers. Another advantage of using machines to manufacture cigars is consistency and the ability to add filters and test the draw resistance during production. Automated machines discard cigars that do not conform to our strict standards to ensure great smoking enjoyment.

FROM SEED TO HANDMADE CIGAR

PLANTING

Tiny, coated seeds are planted into a sterilised growing medium where they germinate. The seeds are monitored closely and grown under strict humidity and controlled temperature. Seedlings are planted in the field – either by hand or by machine. After six weeks in the field, the plants are ready for harvesting. Tobacco leaves mature from the bottom of the plant upward.

HARVESTING

Leaves are picked two or three at a time, starting from the bottom of the plant. Priming takes place on a weekly basis. The positioning of the leaf on the tobacco plant determines its aroma and strength. The bottom leaves create the mildest tobacco. The stems of the leaves are put together and they are taken to curing sheds where they are hung under the roof.

CURING & FERMENTATION

The tobacco leaves change from green to brown in the curing process. After approximately six weeks, the tobacco is packed in cartons, ready for fermentation. A leaf can go through different kinds of curing – e.g. sun drying, air-drying, drying above a fire or at a high temperature – depending on what taste profile the cigar should have.

The tobacco’s characteristics are improved to ensure that it delivers a smooth taste. During fermentation, the tobacco is piled into bunks of 1600-1800 kg. The pressure of the pile generates heat, which transforms the properties of the leaf. Ammonia comes out of the piles during fermentation. The fermented tobacco is packed into storage for a number of months. When the tobacco is ready for sorting, it will be taken out of storage and taken to the conditioning rooms.

SORTING & GRADING

Moisture is applied to the leaves. The moisture makes the leaves easier to handle and reduces the risk of broken leaves. The leaves are ready to be sorted according to their colour, quality and size.

The central vein of the tobacco is removed completely with wrapper tobacco and binder, and partially removed for filter tobacco. Stripping can be done either by hand or machine.

ROLLING

The bulk of the cigar, a blend of leaves called the filler, is held in place by a binder that is wrapped around the filler. The filler and binder together are called a bunch. Once the bunch is made, the very important wrapper is wrapped around it. Cigars are rolled in teams of three: a buncher with two rollers.

INSPECTION & AGING

Every cigar is meticulously inspected. Cigars with imperfections are rejected. Cigars that pass inspection are stored in cedar-lined ageing rooms for at least three weeks. Here, they lose 3-4% of their moisture. The ageing process allows the different aromas and flavours of the selected tobaccos in the cigar to form an exquisite balance. When the cigars are done with the ageing process, they are ready to be packed.

PLANTING

HARVESTING

CURING & FERMENTATION

SORTING & GRADING

ROLLING

INSPECTION & AGING

BANDS & BOXES

STORAGE

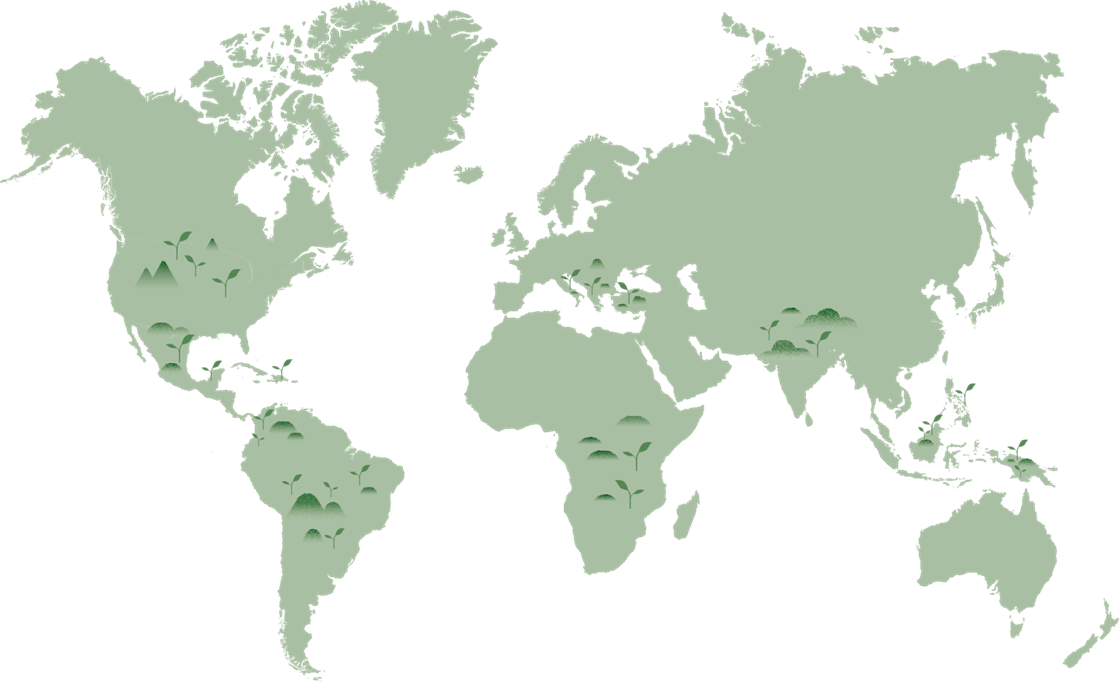

TYPES OF CIGAR TOBACCO AND WHERE IT ORIGINATES

- North America (8)

- South America (8)

- Europe (3)

- Africa (0)

- Asia (7)

- 8

- 8

- 3

- 0

- 7

CONNECTICUT VALLEY LEAF

Grown in Connecticut under thin sheets of cloth, is a thin, elastic leaf that cures to a light, even colour. Grown in direct sunlight, the leaf would be coarse and tough. But by shading it, the sunlight is filtered. Today, shade-grown Connecticut wrapper leaf is one of the world's most expensive agricultural commodities. Connecticut in the US has historically been the source for these wrapper leaves. A combination of good soil, adequate rainfall and abundant sunshine has made it one of the world's premium tobacco-growing regions. Although experiments have been done transplanting wrapper leaf seed varieties from Connecticut to grow in other regions such as Costa Rica, Dominican Republic, Honduras, Mexico, Panama and others, no one has yet been able to duplicate the colour, flavour and texture of the Connecticut Valley leaf. Typically, this leaf is mild in flavour, offering a unique tobacco flavour.

CONNECTICUT SHADE (USA)

Smooth to medium in flavour. Colours vary from lightly golden to red. The tobacco is grown in Connecticut’s Housatonic Valley (also called “Tobacco Valley”) and is sought after and valuable.

CARMEN CUBITA

Like the Dominican Republic, Cuba has an excellent tobacco reputation. Up to now only filler grades, all dark air-cured, can be bought by foreign companies. There are two main regions, Vuelta Abajo, eastern Cuba near Pinar del Rio and Remedios, central Cuba. Both regions have different filler grades, Vuelta Abajo 21 and Remedios 13. Taste wise Cuban tobaccos are rich and spicy, aromatic and high in nicotine.

COROJO

Corojo is primarily used in the making of cigar wrappers. It was originally grown in Cuba, but today it is, among other places, grown in the Jamastran Valley of Honduras and in Western Kentucky in the United States. Today, both hybrid and pure strains of Corojo are used in the production of cigars. Most of the pure Corojo leaves are grown in Honduras, while the hybrid varieties are more widely grown and used.

PILOTO CUBANO

Piloto Cubano is a Cuban-seed, sun-grown filler tobacco which is only to be found in the Dominican Republic. Piloto Cubano is the first widely-used hybrid tobacco because it was the first seed to be taken from one country to be grown in another. It was brought from Cuba to the Dominican Republic by immigrants in the mid-1960s. The tobacco is characterised by its aromatic, slightly sweet, taste.

CRIOLLO

Criollo is primarily used in the making of cigars. By most accounts, it was one of the original Cuban tobaccos that emerged around the time of Christopher Columbus. Criollo means “native seed”, which means that e.g. “Dominican Criollo” may or may not have anything to do with the original Cuban seed. At one point, it was then discovered that when Criollo is grown under cover, as opposed to growing it in the sun as was traditionally done, it can make a very suitable wrapper leaf, given the proper care and conditions. Criollo can also be used as filler. Some of the first Criollo seed grown for wrapper was grown in Nicaragua, but is also grown in other places, e.g. Honduras, Mexico and Bolivia.

MADURO

Maduro is not a type of leaf. ‘Maduro’ simply means ‘ripe’ The most recognised Maduro tobacco type is Connecticut Broadleaf. Maduro is a state of the leaf achieved through extensive fermentation – the natural introduction of a leaf to high temperatures and moisture. During the fermentation process, the natural oils within the tobacco leaf come to the surface, and the colour of the leaf darkens. While this can enhance the flavour of the smoke, the leaf actually becomes mellower. Because of this, there are many Maduro-wrapped cigars on the market.

Canada DAC Tobacco

The Tobacco is Dark Air Cured and is grown in South Western Ontario, Canada. The best tobacco is grown by the Great Lakes. Temperatures and weather in this area have warmer nights and a proper level of humidity that help curing the tobacco. Most of tobacco grown in Ontario is used for filler and binder.ECUADORIAN CONNECTICUT LEAF

Grown in Ecuador, this leaf is thicker by nature and darker in colour. The tobacco-growing regions of Ecuador are misty, eliminating the need for cloth under which the tobacco would be grown. These natural valley mists produce a tobacco leaf that is silky in appearance, oily to the touch, and a slight step up in flavour and strength. Ecuador Connecticut wrappers tend to be richer, with a creamy, slightly nutty element. These characteristics make it the perfect fit for a bold filler blend - thus, it is very possible to produce a medium or full-bodied cigar with an Ecuador Connecticut wrapper.

ECUADORIAN SUMATRA

The Ecuadorian Sumatra is a wrapper leaf grown from Sumatran seed in Ecuador’s cloud-covered climate. It has a smooth flavour and a bit of sweetness to it.

ECUADORIAN CUBANO

This Cuban-seed wrapper is grown in Ecuador in a variety of shades ranging from light to dark. Full-bodied and rich, it is sometimes referred to as ‘Corojo 98’.

ARAPIRACA

More north of Salvador this tobacco type, mainly wrapper, is grown in the state of Alagoas. Arapiraca is also known as the “Capital of smoke” (capital do fumo). The soil is more sandy than in Bahia. The tobacco is dark coloured and has a smooth, somewhat sweet taste.

CRIOLLO

Criollo is primarily used in the making of cigars. By most accounts, it was one of the original Cuban tobaccos that emerged around the time of Christopher Columbus. Criollo means “native seed”, which means that e.g. “Dominican Criollo” may or may not have anything to do with the original Cuban seed. At one point, it was then discovered that when Criollo is grown under cover, as opposed to growing it in the sun as was traditionally done, it can make a very suitable wrapper leaf, given the proper care and conditions. Criollo can also be used as filler. Some of the first Criollo seed grown for wrapper was grown in Nicaragua, but is also grown in other places, e.g. Honduras, Mexico and Bolivia.

BAHIA

Bahia is a region, some 2 hours drive north west of Salvador, in northern Brazil. There are three main regions, Mata Fina, Mata Norte and Mata Sul, each region producing tobaccos with its own characteristics. Mata Norte tobacco is the strongest one. Both wrapper and filler are produced. Bahia tobacco has a typical dark brown colour, giving a spicy, full-bodied taste with a full aroma and a higher nicotine content. This tobacco gives “salt and pepper” to a cigar. Since the 1980’s a wrapper type has been cultivated, grown under shade, using Sumatra seed, but also seeds from other origins are used.

PASADA ESPECIAL

This important grade from Paraguay is, like the Pasado Flojo, a dark air-cured filler tobacco. Its taste is best described as “neutral” and nutty.

PASADA FLOJO

This very important grade from Paraguay is costly and is, like Pasada Especial, a dark air-cured filler tobacco. Its taste is best described as “neutral” and nutty.

BURLEY

Is a fermented filler tobacco, grown in the Baguio and Cabagan area, both on the northern Luzon Island. Taste wise this tobacco is smooth. It is also grown in the region of Caserta, south of Italy.

DARK AIR-CURED (HAVANA TYPE)

Is a dark air-cured, fermented tobacco, grown in the Benevento area, South of Italy. Taste wise it is close to the dark air-cured tobacco types, grown elsewhere in the world.

FLUE CURED

Is a cigarette type of tobacco. Grown in two regions, in the northern part of Italy, between Verona and Venice, and in the Umbria region, Central Italy. Nicotine and sugar levels are medium.

BESUKI NOTA

Is grown and picked in the dry season. Besuki Nota refers to the early Na_Oogst, compared to the real Na_Oogst, due to the fact that it is grown earlier during the season. Besuki Nota is grown in the more southern parts of the Jember area. The tobacco is air-cured, fermented and for wrappers sorted in the same way as traditional NO. Besuki Nota is a wrapper, binder and filler crop. Taste wise it has a slightly sweet taste.

BESUKI NO (NA-OOGST)

Known as traditional Java, grown in the northern part of the Jember area, in Besuki. Besuki NO is sun-grown in the dry season and picked in the rainy season. It is air-cured, fermented and the wrapper is sorted in five basic colours per quality group. Besuki NO tobacco produces wrappers, binders and fillers. Taste wise Besuki NO produces an aromatic and smoky tobacco.

SUMATRA

Sumatra wrapper tobacco is also called “Deli tobacco” because it is grown in the Deli area on the North West part of the Sumatran coast. Sumatra tobacco has been grown since the late 1800s and was for many years a very important source for European cigar wrappers. It is sun-grown. It is known for a distinctive aromatic and spicy taste and good fire-holding capacity. Sumatra wrapper is sorted into 14 different colours and six picking positions. Each of these combinations gives a specific taste. It is a light-coloured wrapper, air-cured in hanging barns and hereafter fermented before sorting. Sumatra wrapper is only sold via the Sumatra campaign in Bremen, taking place in September each year.

TBN

TBN is a fairly new wrapper type, grown in eastern Java, the Besuki area around the city of Jember. The first trials started in the early 1980’s and have now developed into a very important wrapper supplier. TBN is short for “Tembakau Bawah Naungan”, which means “Tobacco grown under shade”, more commonly known as “Shade grown”. TBN is air-cured and hereafter fermented. It is sorted into five different main colours, each having 8-10 different quality grades.

BURLEY

Is a fermented filler tobacco, grown in the Baguio and Cabagan area, both on the northern Luzon Island. Taste wise this tobacco is smooth. It is also grown in the region of Caserta, south of Italy.

DARK FIRE-CURED

This tobacco type is special in its way that the drying is done by using fire, resulting in a typical smoky flavour, taste and aroma. It can be delivered in Loose Leaf or Butted.

ISABELA

Is a dark air-cured, fermented filler tobacco, grown in the Cabagan area on Luzon Island. This tobacco has a sweet taste with a note of tea.

TYPE OF CIGARS

CHURCHILL

7 inches. Ring gauge: 48-50. Parejo.

7 inches. Ring gauge: 48-50. Parejo.GIGANTE

6 inches. Ring gauge: 60. Parejo.

6 inches. Ring gauge: 60. Parejo.PERFECTO

Sizes vary. Figurado.

Sizes vary. Figurado.

WRAPPER COLOURS

OSCURO

The cigars have a stronger and richer flavour. Oscuro, also known as double Maduro, is the darkest maduro wrapper and is almost black. The leaf is left on the plant – and fermented – the longest of all the wrappers and gives it its deep sweetness.

MADURO

Means “mature” or “ripe” in Spanish. The leaf is very dark brown, aromatic, sweet and strong- flavoured. The leaves used for Maduro wrappers must be significantly thicker than others as they undergo a longer fermentation process.

COLORADO MADURO

The wrapper is aromatic, dark brown and has a rich medium flavour. The colour is in between that of Colorado and Maduro.

CLARO CLARO

The lightest-coloured wrapper; light green also called Candela. Candela has a fresh leafy flavour. The colour is achieved by picking the tobacco leaves before the plant has fully matured and by a heat-assisted quick-drying process.

CLARO

Claro is a light tan wrapper picked before full maturity. Claro cigars are smooth-tasting and usually shade-grown. Shade-grown refers to the process of being grown under giant sheets of cheesecloth, which keeps the leaves from being exposed to too much sunlight; this ensures a smooth flavour.

COLORADO CLARO

Light brown to brown colour. Colorado Claro is often a sun-grown wrapper and it has a full-bodied flavour.

COLORADO

The wrapper is reddish or dark brown, robust and rich in flavour.

CIGAR FACTS

The United States is by far the top cigar-consuming country, followed by France, Germany and Spain.

Scandinavian Tobacco Group is a world leading manufacturer of cigars.

The English word “cigar” is derived from the Spanish “cigarro”, which is an adaptation of the Mayan word for tobacco: “siyar”.

Handmade cigars need to be stored in humidors at a relative humidity of approximately 70-72% and at a temperature of 18 °C (64 °F).